The Agri Business Unit guarantees the widest range of components, spare parts and accessories for agriculture

We supply PTO shafts and a rich line of components, both customized and from the catalogue.

All the products are approved according to current regulations.

Technological innovation, functionality, and safety are the aspects that set them apart.

Complete PTO shafts

Standard PTO shafts, with wide angle joints, safety devices, and various grooves. They are available from categories 1 to 10; regarding the wide angle pto shafts, in categories 2, 4, 6, 8 and starting from the year 2025 also in category 10.

The PTO shaft are CE-approved and manufactured in our factories according to the highest quality standards. The internal production allow to verify the single operations and to guarantee a reliable and safe product.

The differences between the TOP LINE and the PRO LINE is represented by the different plastic cover with which we complete our pto shafts: the PRO LINE is equipped with a screen with a corrugated design and a special technology for linking the parts.

TOP LINE

All the categories

PRO LINE

Categories 1,2,3,4

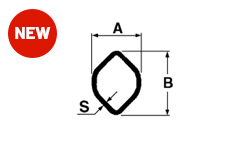

Inner pipes

We produce complete PTO shaft axles from category 1 to category 10 (except 9).

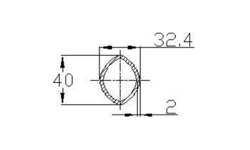

For the W100, W200, W210, W220, and W2400 series, we use cold-drawn lemon profile tubes.

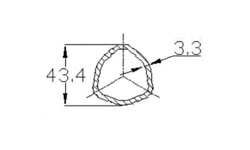

From category 1 to category 8 we use cold-drawn triangular profile tubes.

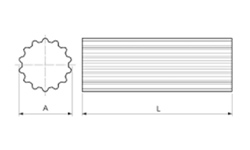

For categories 4 and 6 we can also manufacture the version with tubes having an involute profile.

For category 1 we also have an economic version with

electro-welded and non-drawn “lemon” tube.

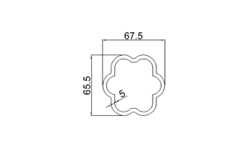

For category 10 we use special 6-lobe tubes.

Yokes

Yokes with push buttons, produced from category 1 to category 10; from category 1 to category 8 also available with 8x32x38 UNI221 grooves.

Yokes with 3-ball quick coupling, produced from category 1 to category 8.

Special, custom designed yokes, produced from category 1 to category 8:

– with smooth diameter, feather key and bolt;

– with smooth diameter and drill hole.

Safety devices

Torque limiter with shear bolt

It is used in those applications where positive torque peaks can occur. The limitation, and therefore the disconnection of the transmission, takes place by shearing off the bolt placed eccentrically with respect to the axis of the joint. To restart the transmission it is necessary to replace the sheared bolt. No adjustments can be made.

Torque limiter with friction discs

It is used both in those applications where positive torque peaks can occur and in those cases where there is a significant inertial force. Limitation, and therefore disconnection of the transmission, takes place through the slipping of the discs (linings). Adjustments can be made by acting on the 8 external springs. The transmission automatically resets once the rpm decreases.

Bidirectional pawl torque limiter

It is used in those applications where positive torque peaks can occur. The limitation, and therefore the disconnection of the transmission, takes place via pawls supported by coil springs which, once the calibration torque is exceeded, radially return to their seat. The transmission automatically resets once the rpm decreases.

Free wheel

This is a device that allows torque transmission in one direction of rotation, avoiding power returns or negative peaks. It is used in those cases where there are machines with strong inertia that, if stopped abruptly, could generate breakage of the transmission or other components.

Wide angle components

- Turning of yokes using a spindle with hydro separator: the yoke remains on the same support but it rotates inside the spindle while the tools always work on the same axis. In this way, axiality and perpendicularity are guaranteed in a single step.

- Induction hardening heat treatment, 52-55 HRC (on the ball).

- Welding grooved bushing (for PTO) and triangular profile bushing (on the tube).

- The balls of the 2 yokes are housed inside the central hole of the guide disc, while its walls slide on 2 sliding rings placed inside the semi-supports.

- Turning of the guide disc in a single phase, including the 3 greasing holes along the larger diameter which have the task of carrying the grease to the yoke balls.

- Heat treatment for carburizing and consequent grinding of the central hole.

The first phases of machining are carried out using numerical control lathes equipped with special spindles which make it possible to guarantee axiality and perpendicularity between the holes. The peculiarity lies in the fact that it is the piece that rotates its position, moving on the same axis, depending on the area to be worked.

The broaching operation is the second phase of processing: Ama Cardan is equipped with 20-ton systems which foresee the simultaneous use of 3 different tools. The range of tools allows us to make both all trilobar profiles (for fitting forks on iron tubes) and the main UNI grooves: 1 3/8 Z6 – 1 3/8 Z21 – 1 3/4 Z6 – 1 3/ 4 Z20 – UNI221 8x32x38

Protection systems

The TOP LINE and PRO LINE production lines are equipped with protection systems, which can be applied both on standard PTO shafts and on models with safety and/or constant velocity devices.

Furthermore, for categories 1, 2 and 4, we offer the Flex cover, which allows the protection to be connected directly to the implement cart, in the event that it is not possible to assemble the shaft cone

TOP LINE

For constant velocity pto shafts

For standard pto shafts

PRO LINE

For constant velocity pto shafts

For standard pto shafts

FLEX COVER